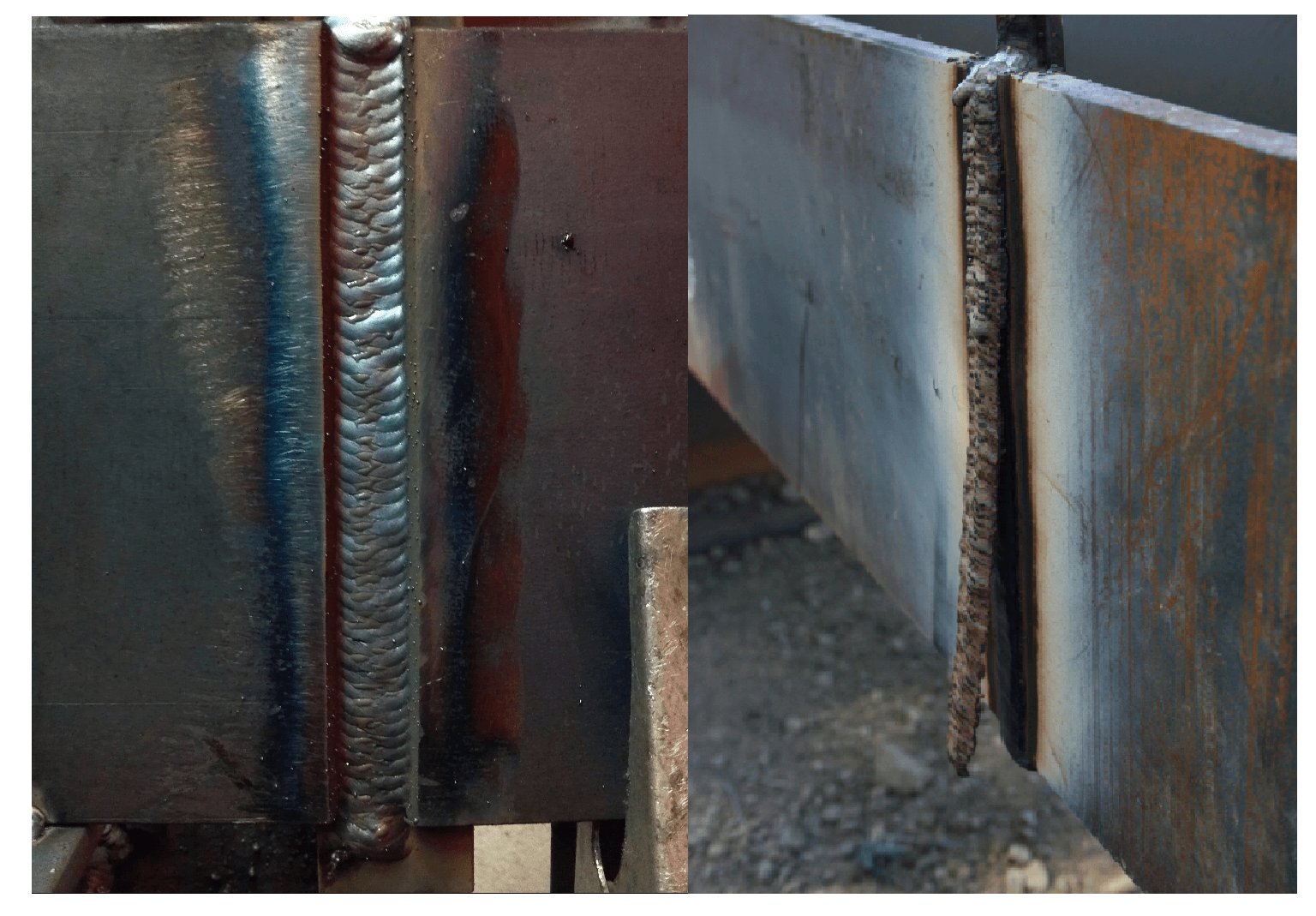

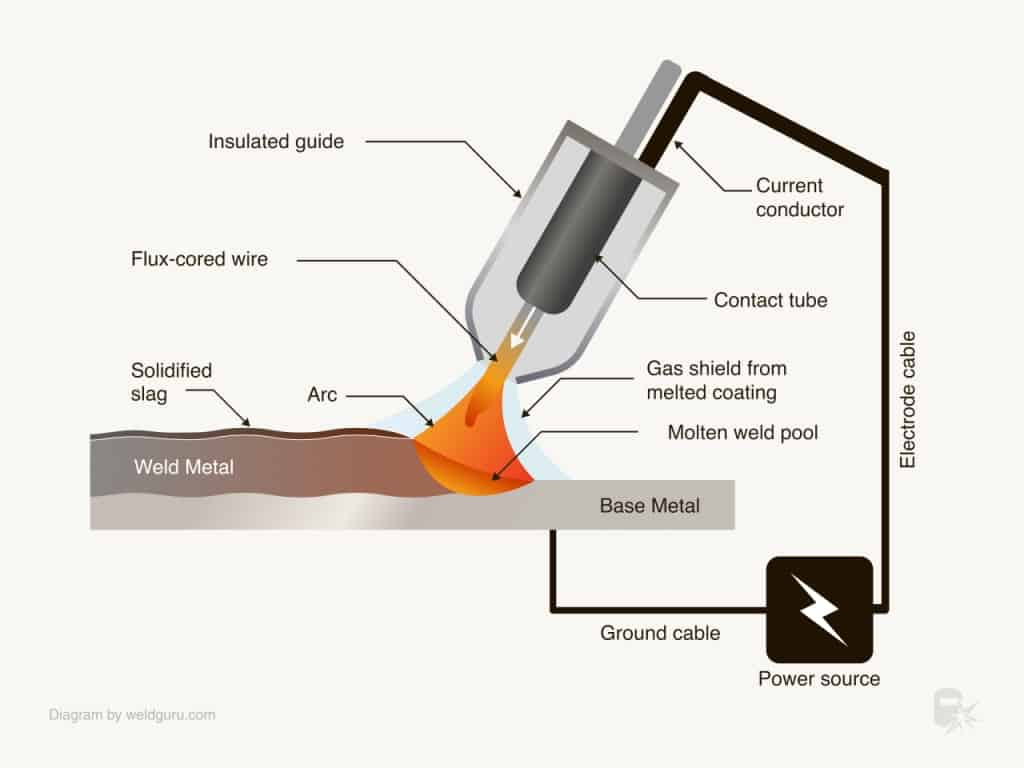

Vertical and flux-cored wires. With the proper flux-cored wire, you can weld vertically both up and down. If the number before the “T” in the wire’s designation is 1 (Ex1T-x), you can weld vertically. But if it’s 0 (Ex0T-x) you cannot. Flux-cored wires are tubular, filled with flux material that creates slag.. Vertical up-flux core welding typically requires a voltage range of 22-29V, with a wire feed speed of 75-250 inches per minute. Amperage settings can vary from 90 to 280A depending on the wire size and material thickness. Vertical up flux core welding, frequently employed in the construction and shipbuilding industries, demands precise settings.

Flux Cored Arc Welding PabloaresRichard

The Complete Guide to FluxCored Arc Welding Welding Headquarters

Flux cored arc welding dopkm

Stainless Steel Flux Core Welding (with Gas) YouTube

VERTICAL Flux Core Groove Weld D1.1 Weld Test 3G Uphill YouTube

Getting to Know Fluxcore Wire

Flux Cored Arc Welding Basics YouTube

Flux core welding YouTube

![FLUX CORE ARC WELDING [BAGIAN 1]](https://i.ytimg.com/vi/9C-npzXNyzM/maxresdefault.jpg)

FLUX CORE ARC WELDING [BAGIAN 1] YouTube

How to weld with flux core? What Is Shielding Gas Used for Fluxes Cored Arc Welding? Flux

Welding Common Joints Using Flux Cored YouTube

What is Flux Core Welding? WeldingWatch

What is FluxCored Arc Welding (FCAW aka Dual Shield Welding)? TWI

Trouble with vertical up flux core r/Welding

What is FluxCore Arc Welding (FCAW) & How Does it Work?

5 Tips for Flux Core Welding Beginners How to Weld with Flux Core YouTube

Flux core welding test 3g vertical uphill and 4g Overhead welding test

How to Set Up A Welder For Flux Core In 11 Mins Flux Core Welding For Beginners Gasless

Insider’s Guide to FluxCored Arc Welding (FCAW) Insider

Flux Core Welder Beginner Welding Without Shielding Gas Affordable Flux Core Welding At Home

#welder #welding #fluxcoreIn this video, Kase Ford, Welding Instructor at Tulsa Welding School, shows a fluxcore vertical weld.Tulsa Welding School was found.. 2. For test assembly 4.2A the fillet weld lap joint and fillet weld T-joint are required. e. Test assemblies 4.1, 4.2A and 4.3B shall be welded in the vertical and overhead positions. f. Vertical weld test assemblies shall be both upward and downward progression. g. Test assembly 4.4 shall be performed with 18 gage ASTM A570 Gr.40 welded in the.